FLUX STONE CRUSHER FEASIBILITY

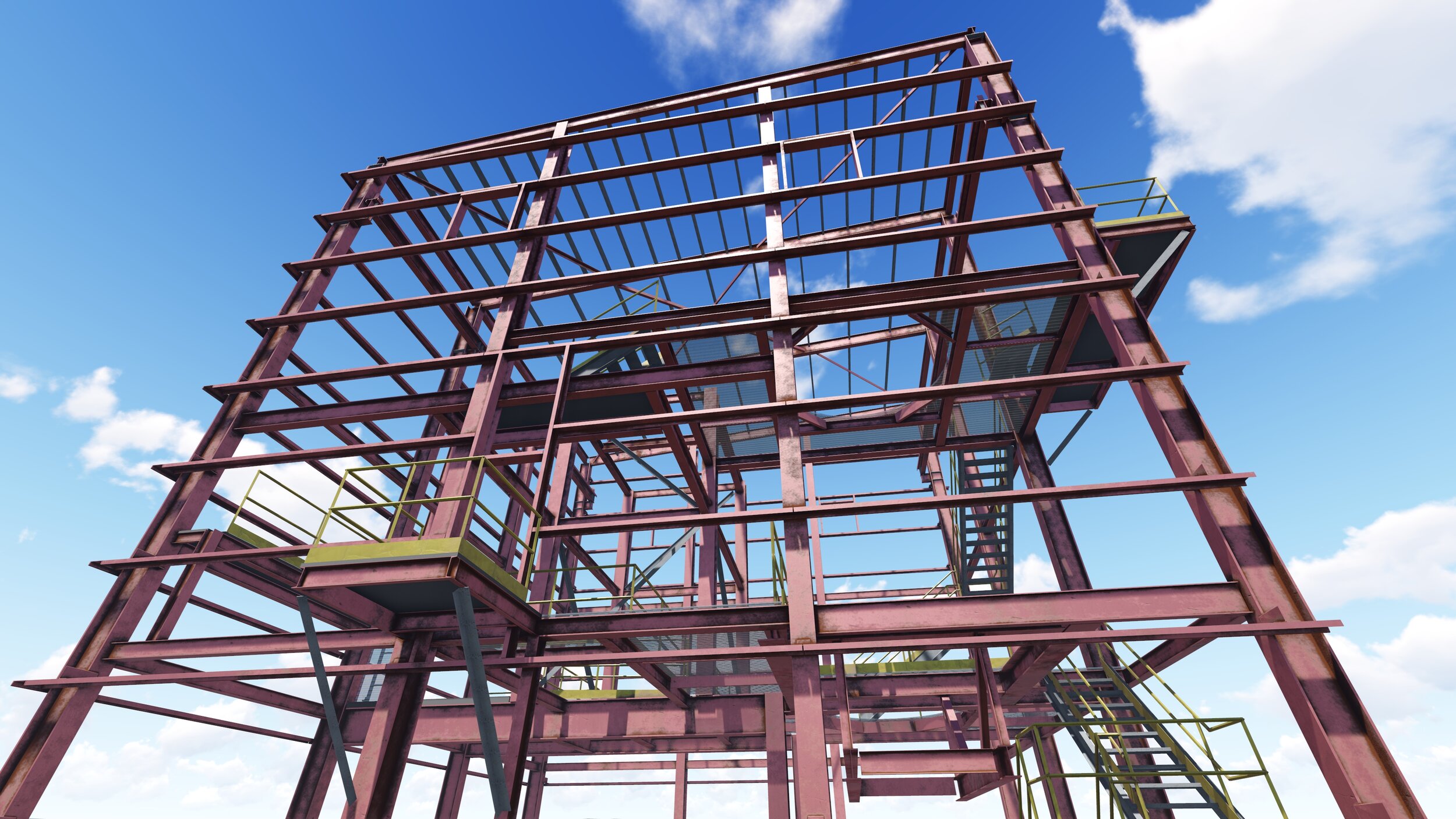

AMI was contracted to provide engineering services for a feasibility study on the addition of new flux stone crushing circuit within an existing process. The current system was not performing at an adequate level to maximize production. Two different crushing systems, including retrofitting the existing crusher, were considered for the design with several layout options tailored to each process. AMI considered the effects of outage time, equipment and installation costs, reliability, and production in the feasibility study. Preliminary layouts were provided as drawings overlaid on existing plant PDF drawings to show the different layout options and highlight any potential issues moving forward with the final design and installation. Preliminary designs included structural modifications, new access platforms, equipment layouts, preliminary chute design, preliminary conveyor specifications, and maintenance access. A detailed AACE Class 3 Cost Estimate was provided for the different options to encompass the complete scope of work. Installation writeups provided the client with helpful insights of outage durations and construction timelines. AMI worked with the client and vendors to obtain information on the preferred equipment along with cutsheets and preliminary models. The final deliverables of the project were tailored to support the client in making a final decision and move the project into the design phase with a clear budget and scope of work.